If the shoe fits: Shoes as a technological product

Shoes are worn everyday, but making them in a classroom is rare.

Teacher, Amy Jansen-Leen has experience working in costume props and also runs her own millinery (hat making) business.

Amy shared her skills and experience to help her students create their own shoes, using the sole and platform of existing shoes or constructing them from scratch.

Nature of technology

This project was a great opportunity to think about shoes as a technological product and for students to realise how understanding from technology and other disciplines inform decisions in technological development (Indicators of progression, Characteristics of technology, level 4).

The effect of shoes on posture, how shoes function, the anatomy of the foot, and the effect of weight distribution of the body on the foot in particular designs were all explored.

Making shoes provided an authentic context for testing whether the shoe design could be called a good design or a bad design.

Students explored whether there was a good match between the physical nature and functional nature of the shoe in their shoe design (Indicators of progressions, Characteristics of technological outcomes, level 3).

Creativity

An avant garde edge

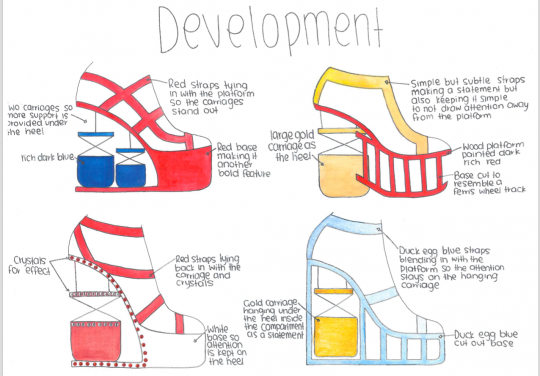

Encouraged to design with an avant garde edge rather than everyday streetwear – the students were free to be very creative in their designs.

Design and innovation are key concepts in the technology learning area. Amy found exploring these concepts provided a starting point that encouraged abstraction and innovation in the students' design work.

The students researched forecasted fashion trends for the following summer as their starting inspiration. They gathered information about their chosen forecasted trend. The students then came up with the social environment in which they envisaged their shoes being worn.

The mechanics of a shoe

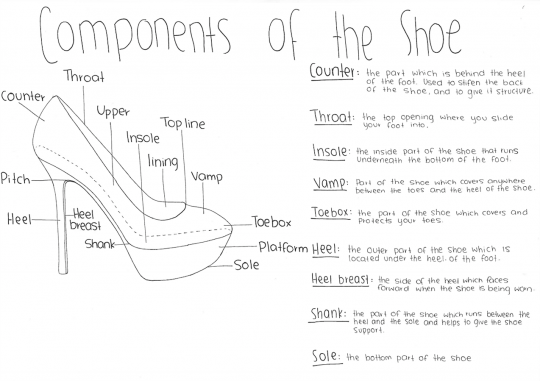

The shoes had to be functional and to be able to fit a person – the student themselves or a stakeholder. The students learnt about the mechanics of a shoe by trying on lots of shoes and deconstruction.

Resourcing and approach

Accessing expertise and solving problems

As well as her own background in shoemaking, Amy called on some well known shoe making companies in New Zealand. These willingly shared their information on the shoemaking process.

The school’s gardener had also made shoes for orthotic purposes. She shared her knowledge of how the foot operates and moves and rolls as we walk. She was able to offer feedback to students as they designed and trialled their shoes.

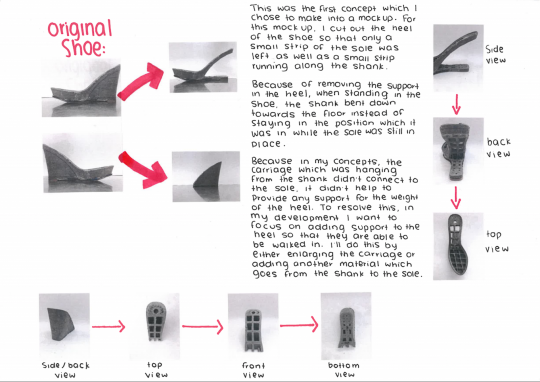

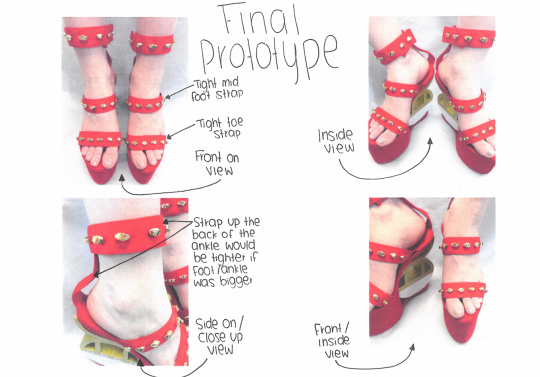

Some of the shoe prototypes collapsed on wearing and had to be redesigned. These issues with construction gave opportunity for lots of problem solving and learning about balance and weight distribution within the shoe structure.

The students began by learning about the components of a shoe and using the correct vocabulary to describe these. They were also encouraged to visit second hand clothing outlets to find shoes that would provide a suitable base for their shoe design.

Resources and equipment

Amy limited the design range to sandals or platform shoes because she thought they were feasible styles to construct using the tools and equipment available within the classroom.

The equipment and materials made available to the students included:

- equipment in the school's workshop – lathe, pliers, hammer, clamps, contact adhesive, a variety of different strength glues, sandpaper, and heat gun

- materials – cork tiles, rubber, foam (various thicknesses and strengths), felt, leather, cotton webbing, a variety of embellishments, upholstery tacks, resin, raffia, polystyrene, worbla (flexible plastic that reacts to heat to create shape and form)

- cutting and shaping tools – craft knife, scissors, jigsaw, sewing machine, leather hole punch.

Students also sourced their own additional materials.

Amy also referred to some videos on shoemaking:

Assessment

NCEA level 2

This was a year 12, NZC level 7, NCEA level 2 project.

All projects of the year 12 textiles materials programme include a fashion drawing component. As well as the shoe project, the students complete a wearable art and a fashion drawing project.

Students then use each of these to contribute evidence to the external Assessment Standard 91337 Use visual communication techniques to generate design ideas.

Amy finds that this year-long approach to gathering evidence gives her time to work with individual students and offer guidance on improving their design work and drawing throughout the year.

All students passed their externals and five students achieved at excellence.

Exhibition

Art Showcase

The students exhibited their shoes alongside the student art works, performing arts, and music performances in the school's Art Showcase held at the school.

This exhibition was open to the school and wider community.

It is an annual event which gains a lot of interest every year.

The public enjoyed seeing such innovation and creativity from the students.