Colour on metal: Design and functional modelling in year 6

Teaching inquiry

How can I grow the design skills of my year 6 students at the same time as I am developing their understandings about functional modelling?

Introduction

Coastal Taranaki School teacher Sally Laing found that designing, making, and decorating frames for mirrors was a great context for helping her students:

- learn a new technique for decorating

- increase their understanding of functional modelling.

Background: The workshop

Sally Laing is not only a teacher at Taranaki Coastal School; she is also a highly regarded designer of enamelled jewellery.

When she learned that US jewellery designer Deb Karash would be running a three-day “colour on copper” workshop in Melbourne, she had to go.

As well as ideas for her own work, she returned from the workshop with ideas for her teaching.

Karash’s “colour on copper” techniques

Deb Karash’s techniques involve applying colour to textured and patinated copper.

First, she uses a small paintbrush to apply patina to a very clean copper surface, supporting the metal with kebab sticks to avoid touching it with her fingers.

Once the patina is dry, she applies colour with Prismacolor pencils, blending it with old toothbrushes. When satisfied with the result, she seals it with spray-on matt polyurethane. Repeating this process several times gives the colour richness and depth.

I took with me and used some pieces that I had already textured at home – I was keen to try the colouring technique on as many different surfaces as possible.

Sally Laing

Deb also demonstrated how tube spacers, brass tacks, and rivets could be used to join pieces together and how spacers could be used to create a 3-dimensional effect.

The spacers and rivets were themselves part of the design, and sometimes doubled as a space through which to thread a cord (a good example of form following function).

|

|

Workshop organisation

Sally was interested in how the workshop was organised:

The workshop room was well set out so that participants could see the process. Deb scaffolded us into using the process straight away. Pieces of copper were pre cut and patinated, waiting for us to get started. This gave me ideas on how I could set this up at school. Later, while the first pieces were drying, we cut and prepared our own shapes.

Sally Laing

Planning for using the techniques in the classroom

Sally could see that if using the patina technique in her classroom, she would need to find a workable way of ensuring that the students kept the surface of the copper very clean, so that the patina would adhere.

Waiting for the patina and polyurethane to dry would not be a problem given the break between classes.

Neither should resourcing be difficult:

Most of the materials – recycled copper, bamboo sticks (for applying the patina), spray-on polyurethane, and so on – are readily available and not expensive. Lime sulfur or gesso could be used instead of the patina as it is cheaper and does the same job. Prismacolor pencils are expensive, but I thought that, to start with, the students could practise the technique with crayons on MDF (medium-density fibreboard) in our current mirrors project.

Sally Laing

After returning from the workshop, Sally created a presentation to capture the techniques she had learned and the understandings she had gained.

The mirrors project

Sally was keen to incorporate the techniques she had learned into her teaching. Her year 6 mirrors project provided an opportunity to use the techniques – but without the expense and technical sophistication required for working with metals and creating jewellery.

Adapting her year 6 mirrors project to include making a unique, rendered MDF frame meant that the students could start learning the “colour on metal” technique – but on a larger scale and with cheaper materials.

The curriculum focus for the unit was the following:

- outcome development and evaluation at level 3

- technological modelling at level 2–3.

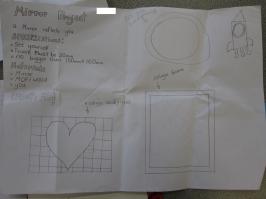

The students specified the attributes, did some initial drawing, and then cut a pattern for their frame from coloured paper.

|

|

They were given the dimensions of the available MDF and, together with Sally, determined the most suitable thickness for their frames.

The students used the scroll saw to cut a template for the frame out of thick card. This helped them see how their concept would work in practice and whether it would meet their specifications. They used this template as a guide for cutting the MDF frame. When they had completed the cutting, they sanded the edges smooth.

Sally demonstrated the crayon rendering techniques on a partly coloured-in frame. The students then tried the techniques themselves.

The students modelled their colouring ideas straight onto the MDF and also onto MDF that had been coated with gesso (a white matt undercoat paint).

One student, whose design was of Mount Taranaki, could clearly describe the difference between using the technique on plain MDF and on the gesso coated MDF:

It's easier to do on the gesso-coated and sanded surface, and the colour goes brighter.

A year 6 student

Sally found that the students were generally quite intuitive in their use of colour. Some students also used a pokerwork machine to add texture.

Sally encourages her students to develop confidence in their own design:

I like the students’ own voices to come through even if this is at the expense of perfect outcomes. Giving students a creative voice is important.

Sally Laing

The students discovered that they needed to colour the inside edge of their frame and a little of the underside, as both could be clearly seen in the mirror.

Outcomes

The students came to understand the value of modelling. Modelling ensured that the frame would fit the mirror, and modelling kept them focused on their design.

Modelling also helps ensure that students don’t end up with outcomes that are very different from the design.

|

|

Most students succeeded in satisfying the modelling indicator for the level 3 outcome development and evaluation component (technological practice strand):

- Describe design ideas (either through drawing, models, and/or verbally) for potential outcomes.

On reflection, however, Sally realised that the modelling in this project was entirely in the context of the students’ own practice. This meant that they did not satisfy the level 2–3 indicators for the technological modelling component, which relate to broad understandings of the role of functional modelling in technological practice. These understandings can only come from exposure to varied examples drawn from the modelling practices of actual technologists.

These level 3 indicators make explicit the need for specific examples:

- Discuss examples to identify the different forms of functional models that were used to gather specific information about the suitability of design concepts

- Identify the benefits and limitations of functional modelling undertaken in particular examples

What next?

Sally teaches enamelling in some of her classes, and she could see that the colouring technique she learned from Deb might be a useful alternative, particularly for a bigger piece such as a candlestick or bowl.

Later this year, Sally plans to have her year 6 students use Deb’s “colour on copper” technique to create small metal photo frames. This time, the students will move on to using the full technique on metal and on a smaller scale, incorporating functional modelling as an essential part of their process.

Sally has also recently had a group of year 7 students making desk tidies and developing understandings of modelling within technological practice. The students added colour to their desk tidies using Sally’s adaption of the Deb Karash technique.

Further information

Sally Laing’s enamel jewellery work

Penland Book of Jewelry: Master Classes in Jewelry Techniques