Developing a sports bar

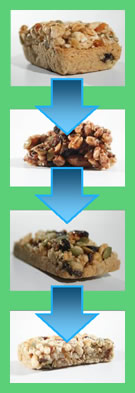

The bars visual development process.

Year 12 Food Technology students Sarah Adam and Danielle Sutherland are both athletes and know that good nutritional recovery directly after exercise is vital. They found that existing sports bars in the market didn't meet their needs and decided to create their own 'repair and recovery' sports bar.

Brief and key factors

To create a natural (not processed) bar that is designed to consume after exercise and is light, not too sweet and cost effective.

The key factors for the project included:

- cost – the ingredients had to be affordable

- size – the bar had to be storable and have appropriate proportions

- skills – the project had to fall within the girls existing abilities

- appearance – the bar should be natural/healthy looking.

- taste – the bar should be not too sweet

- fit for the purpose

- repair and recovery

- use of specific ingredients and nutrient enhancing preparation methods.

The girls had identified that there was a gap in the market for natural banana-flavoured products, so this was also incorporated as a key ingredient.

Client

Early in the year, the students met technologists Aditee Naik and Bronwyn Munro, who agreed to serve as both clients and consultants throughout the project.

Aditee, a food scientist with a Master's degree in sensory evaluation, helped us with professional sensory evaluations, so we could develop an understanding of what the perfect product would be. Bronwyn works for sports nutrition company Horleys and has provided our team with her professional opinion and advice to improve our bar, and has sourced relevant products that we would not have been able to access otherwise, the girls said in their project report.

Racey Recovery report (PDF, 2 MB)

Research

Disassembling current bars on the market.

The girls examined existing bars on the market, breaking them down to find the ingredients and their ratios. The team found that many were very low in fruit and nuts, had a dense, processed texture and were often far too sweet. They also lacked the right balance of protein and carbohydrates to be useful for quick recovery directly after exercise.

Trialling

The girls trialled their first recipe which consisted of a heavier and more solid base with a separate topping to give texture, and colour with nuts, fruit and chunkier ingredients.

As each trial developed, the girls changed the ingredient ratios and methods of preparation of these two recipes to meet the key factors. Each recipe was also evaluated on its nutritional value and taste while taking the key factors into account.

Trialling different types of bars.

Over time, ingredients such as chocolate were removed to reduce the heaviness and overall sugar content. The butter content was minimised to reduce saturated fat levels while still maintaining consistency. Bran was also mixed with standard flour for improved consistency and nutritional value.

The girls tried various methods of incorporating banana into their recipe. They started with store-bought liquid fillings, but found that they made the mix too moist (also reducing the shelf life), too sweet and/or too artificial tasting. Dried banana chips worked far better with the existing ingredients and were eventually blended into the topping recipe.

The girls' first major issue during the trials was that the topping and base layers weren't sticking together well, making for a messy, crumbly sports bar. The girls tried blending the topping ingredients together for the next trial.

"Feedback from taste testers showed that although this bar held together a lot better it was not as visually appealing as the original topping because it looked more 'processed'. To overcome this we created a three-layer bar with the base, a layer of the processed topping to hold the bar together, then the original topping to maintain the natural appearance."

Once the recipe was finalised, the girls experimented with different cooking times for each layer to get the best taste and texture until the process was perfected.

Production

The size and shape of the bars also had to be considered to ensure the product was truly fit for purpose.

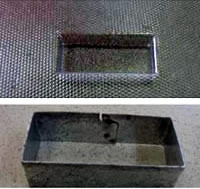

Mould and metal cutter for bars.

Throughout the early trials, the bars were produced as a single slab, then cut into bar shapes. This created inconsistent-sized bars that were messy and unprofessional in appearance. The size and shape of each bar also affected its texture and taste, as some had more exposed surface area then others.

To help create a consistent and professional product, the girls talked to their Materials Technology teacher.

"Mr. Bennett guided us towards making a vacuum formed mould to shape our bars in so they could cook individually. This worked well and we got perfect shaped and sized bars every time."

As the trials continued, the girls realised that the vacuum form mould was inefficient, as it could only shape one bar at a time. To speed up manufacture the girls went back to the Hard Materials room where they folded and spot welded a metal frame together with the same shape as the vacuum form mould.

"This metal 'cookie cutter' helped us to make the bars in a uniform shape and size with far less labour and time than the vacuum formed mould."

Packaging

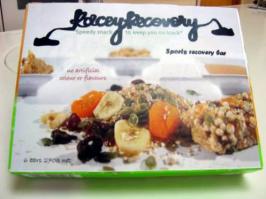

Cooked bars.

To create a fully realised product, the girls also created packaging for the Racey Recovery sports bar. After trialling several designs with stakeholders for their feedback, the girls used the school's photography room to take shots of the prototype bar for the final packaging design.

Final product

After eight different recipe trials and numerous sensory tests, consultations and evaluations, the girls arrived at their final prototype.

"The taste, texture, appearance and size of the prototype bar are exactly as we wanted them, and feedback from stakeholders and taste testers shows that the Racey Recovery the bar is enjoyed by everyone. The nutritional values we calculated also show that we have stuck to our brief, creating a repair and recovery bar that is truly fit for purpose, with both protein and carbohydrates combined with other ingredients important for muscle recovery."

Final package.

See also: