Testing in food processing

Introduction

In this snapshot, food technologist Carol Pound gives guidance on helping students understand and apply authentic testing while food processing in a school classroom setting.

Background

Carol Pound, a food technologist, assisted with the development of the NCEA processing standards – for example, at level 1:

AS91082 Implement basic procedures to process a specified product

AS91083 Demonstrate understanding of basic concepts used in processing

Modern food technology has a strong focus on processing and its associated testing. The intention for these assessment tools is to encourage students and teachers to learn about processing and testing for food technology courses.

The purpose of testing in food processing

In industry the supervisor of a production line will follow an established process, including testing, knowing that the same product will always be produced – within the facilities and equipment available the same amount of product will be produced at the same quality and cost, with the same degree of safety, and it will fit the packaging. Company profits are dependent on reliable production.

Testing is a critical aspect of food processing because:

- a commercially made food product is usually expected to have a long shelf life

- consistency, food safety, and a nutritional composition to match the label are essential

- food technologists need to ensure that the process can be replicated.

There are generally three categories for testing during food processing:

-

Quality assurance

This includes such things as testing for end product quality – to ensure the flavor, colour, and texture is as expected, the size is correct, and the composition matches the label.

-

Consumer safety

This testing ensures that the product is processed so that it is safe to eat. Examples include a HACCP (Hazard analysis and critical control point) plan and its associated testing to recognise any high-risk ingredients and manage these during processing to prevent microbial growth.

Testing involves checking that food and hygiene plans are adhered to. For example – that correct clothing is worn for processing and the necessary safe storage conditions and shelf life of the completed food products are documented and followed.

Allergens, toxins, and foreign materials (for example, plasters, plastic) may also be tested for.

-

Technical issues

Food technologists need to consider the budget, including both costs and yield. Testing here includes evaluating the suitability of the processing equipment available – in terms of the product cost and finding the best match of equipment to produce a product with desired end properties. For example, an ice-cream product may require a certain amount of air to produce the correct creamy consistency. In industry the manufacturer may have a range of industrial equipment that performs this function. In the classroom this may require evaluation of different mixing methods and determining which equipment (for example, a food processor, planetary mixer, or a hand-held beater) gives the best ice cream.

Testing may also be carried out during the development phase to establish the best final processing method to use.

Relevant testing

A food technologist will have well developed specifications for every product they process. Any testing must be relevant to the product specifications.

It’s a good idea to question students about the relevance of their planned testing. Students must be able to argue that each test actually provides them with information that is relevant – to ensure that the product meets its specifications.

Carol Pound

For example, when considering quality assurance, students could be testing the subjective properties of the product such as color and sensory testing, including taste and texture. In addition, they could be testing the objective properties of the food product, such as viscosity, set, coverage of coating (for example, on chocolate éclairs).

Testing equipment

Industry standard testing equipment is not required in the classroom. Where students have an industry mentor, they may have access to industrial food industry testing but this is not essential at all. It is more a matter of precisely recognising the product’s specifications and then developing tests, mainly using the equipment available in the classroom.

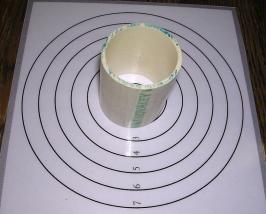

Carol suggests that teachers may wish to acquire a few small items of equipment that are mostly available from hardware stores. See the slides below for her suggestions.

Examples of tests

Carol provides a suggested list of tests below. This list is a starting point. It is not exhaustive. Students and teachers will discover their own ideas for testing as they experiment with their food products and their specifications.

Suggested tests in food processing (Word 2007, 25 KB)

Carol used this presentation with secondary teachers when running workshops on processing. There are further testing suggestions here and it also includes the names of industry tests and the equipment used during food processing.

Product testing during prototype development (PowerPoint 2007, 108 KB)

Testing informs processing

Students develop a flow diagram for processing and testing. The diagram should be robust enough to ensure that if anyone followed the plan they could replicate the product.

The flow diagram should have custard on it – it is a working tool that the student should be regularly referring to as they process the product!

Carol Pound

Some of the tests will only be used in the development stage of the product and others will be integral in the final processing of the product as well.

For example, if a processing plan was set up for a batch of biscuits – initially, students could weigh the ingredients, and then they could compare this with the weight of the final mixture.

This would identify the loss of mixture from scraping it out of a bowl and transferring to other containers. Students might not carry out this test when finally processing the biscuits, but could take this information into account when calculating yield.

Calculating yield and cost

At level 8 of the curriculum students are expected to choose processing operations (techniques and tests) and compare predicted and actual costs and calculate yield per unit of production. (See AS91643 Implement complex procedures to process a specified product.)

At this level the typical costs students take into account should be similar to those in an industrial food processing operation. There are inexpensive small meters available that householders use to monitor the power usage of different appliances. A simple method to calculate the energy use of appliances is given on ENERGY.GOV, Estimating appliance and home electronic energy use.

Carol has used the slides below to demonstrate the industrial considerations when calculating yield and cost in a fish factory.

Starting in the junior school

Students can develop their knowledge of generic processes and key understandings around testing in food processing in years 9–10.

Teaching students the concepts of testing at a junior level allows them to identify the attributes required of a food product and understand the concepts behind testing so that at level 8 of the curriculum they are ready to develop their own tests to process a food product.

Identifying attributes

The first step in establishing testing is to identify the attributes required of the food product. These include the attributes related to food safety and quality. The processing and the testing, including the responses to the testing feedback, are then identified.

Transferring understandings

Students can also learn to transfer the rationale behind one type of test to another.

For example, when testing the setting point of jam, a sample is placed on a chilled saucer. If a ripple is created when a finger is drawn across the jam, the jam is likely to set. The student can record the processing time and temperature to achieve this setting point.

The understandings of temperature and processing time and their impacts on viscosity could easily be transferred to processing custard – the jam has to be at a certain temperature, as does the custard when establishing preferred viscosity.

Carol suggests prompting and encouraging students with questions to revisit their previous experiences of testing and translate this to their next product.

- What were the attributes you were looking for in jam?

- What testing did you carry out to ensure the jam set?

- What similar attributes can you think of in custard?

- Would any of the testing you carried out when processing jam be suitable for custard?

- What other tests might you need?

Equally, other students’ practice and technological experiences such as industry visits, visiting speakers, videos and film clips, work experience, and their whānau or families’ experiences in food processing can assist with developing understandings.

Science and understanding food

Teachers can assist students to develop their understanding of processing and testing by discussing food as a material and also developing their food chemistry knowledge. Free online courses are now available to build teacher and student knowledge of food science.

Students may come with limited experience of practical food preparation and little understanding of why ingredients are processed in a specific way. One way to develop these understandings is to let students experiment and play with ingredients and provide questioning on the outcomes.

An example of this approach to teaching food technology is seen in the teaching snapshot Technological products in food technology.

Students could also make the same product using different processing methods. For example, a class could make pumpkin soup by baking or boiling or microwaving the pumpkin and then processing the cooked pumpkin using various pieces of equipment such as a stick blender, a masher, and a food processor. Students could carry out sensory testing of colour, flavour, and texture on the finished products. The class could discuss enhancing flavor by altering the processing rather than adding ingredients (for example, caramelising the pumpkin through roasting rather than adding sugar).

Radio NZ has archives of useful episodes in their This Way Up series that can assist with developing understandings of the science of food products, for example:

TED Ed also offers resources. For example, see: The chemistry of cookies.

At curriculum level 8 students could be considering biology concepts. This could include the specific types of bacteria that are produced in foods and that need to be addressed during processing to make the product safe to consume.

Understanding food allergies and what is in ingredients is important when the product students are developing may be for a person with a food allergy. Gluten is widely distributed in commercially prepared ingredients as well as in a variety of grains. Preparation of food in an allergy-free food preparation area needs to be considered when, for example, developing a product to address a peanut allergy.

Foreign object testing is also important. Setting up a procedure to ensure that all of the equipment planned to be used in processing is set out and photographed before and after completing processing is one way of testing this. The Fonterra botulism scare is a useful case study to demonstrate the importance of checking for foreign bodies. See, Fonterra: Truth comes out.

Student outcomes

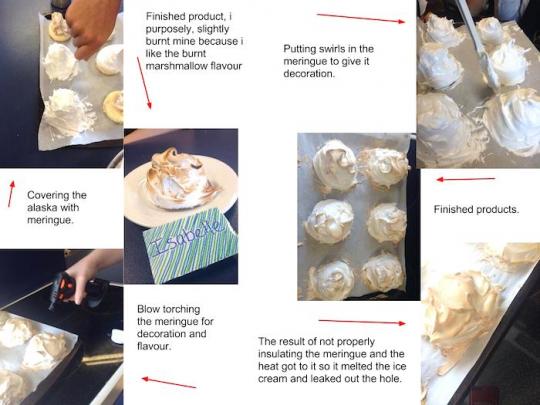

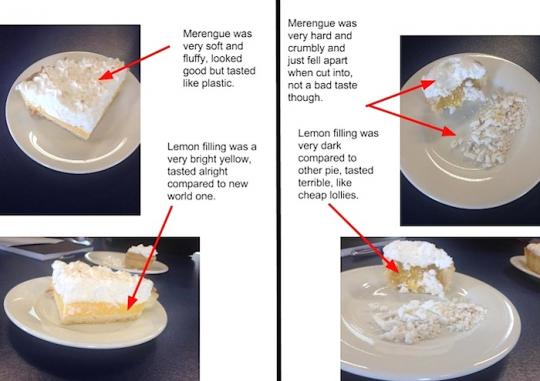

Here are some examples of students’ work in learning about processing.

Lemon meringue pie: Final evaluation against the specifications (Word 2007, 8 MB)

Related videos

Real food, real fast (02:35)

Students were set a brief to develop a faster, fresher, healthier takeaway based on an analysis of a traditional recipe....

A food bag for a family dinner (03:31)

With a focus on using seasonal produce and their families as stakeholders, students produced great recipes and food bags for a family dinner....

Food technology and science (03:47)

Brenda Whycherley and Vanessa Austin of Edgecumbe College approach food technology and science with a holistic view.