Incomplete prototype earns scholarship

Year 13 student Genna Ackroyd received scholarship for her report on an incomplete prototype. Her story shows that an incomplete prototype may be an acceptable and successful scholarship submission under some conditions.

The ideal hockey bag

Genna, a keen hockey player, decided to make her ideal hockey bag for her year 13 project and scholarship submission.

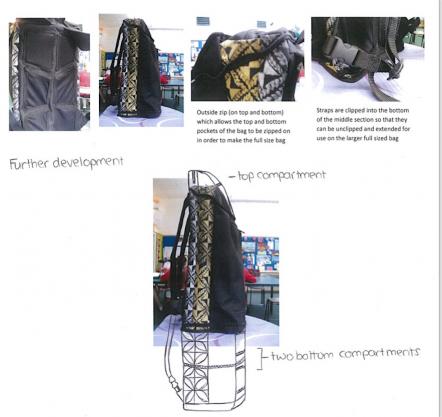

She designed the bag with four separable compartments. The middle compartment could be used as a bag in its own right and contained various pockets, including secure storage for keys and a cell phone. The other three compartments could be zipped to the central compartment to provide storage for such things as shoes, school folders, and wet clothes.

The user could configure the bag to suit the requirements of the day, whether going to school or travelling to a tournament.

By the time Genna had to finalise her report, she had only been able to complete construction of the middle compartment. However, this prototype was enough to provide extensive evidence that the completed bag would be fit for purpose in its broadest sense:

- the ergonomic fit of the bag was tested

- the compartments could be zipped on or off

- the printed design on the fabric was aesthetically pleasing and culturally acceptable

- all materials had been tested, apart from the PVC for the base of the bottom compartment

- the materials and construction techniques were strong, durable, and reliable.

Genna modelled the remaining compartments as annotated sketches that clearly showed what the fully realised outcome would look like.

Materials

This scholarship submission provided extensive evidence of evaluation of materials for outcome development and evaluation.

The design and features of the bag required multiple materials. Two visiting technologists got Genna thinking about a wide range of materials and their construction:

- Angela Carter is a fashion designer who repurposes materials such as plastic bags into garments. She encouraged Genna to explore sailcloth and roofing material as possibilities for her bag.

- Estelle Pemberton is a bag designer. She encouraged Genna to think about printing on fabric, stabilising bags using unusual materials such as those used by milliners, and seeing the inside of a bag as equally important to the outside.

Genna initially sourced materials at fashion retail outlets. She then discovered the Canvas Company, who had a broad range of textiles. Cost, weight, durability, and waterproofness were all contestable factors – and cortex canvas was the final choice.

The bag design also needed elastic, padding, and zips:

- elastic with good recovery was needed to hold the hockey stick on the side of the bag

- padding for the back and bias binding for the edge of the padding and straps all had to be trialled and selected

- open-ended zips that were the correct length had to be imported.

For the panels of the bag, Genna applied a design that celebrated New Zealand identity. The design involved extensive trialing to develop a pattern repeat that would be appealing and to choose paint colours that would give maximum impact on the fabric.

Construction and the final outcome

Sewing thicker canvas material can be very challenging on a domestic sewing machine. Despite trialling size 90 and 100 needles and finally a leather needle plus various sewing feet attachments the machine continued to skip stiches and required some parts of seams to be redone to secure them satisfactorily.

Small corners, multiple compartments, multiple layers and installing zips in a fabric with little give all make for challenging construction.

After sometime spent on this construction, Genna approached a professional canvas maker to finish off the middle section. A canvas maker charges by the hour. The clear manufacturing instructions provided by Genna ensured that costs were kept down for this outsourcing.

The school subsequently purchased an industrial sewing machine and Genna used it to complete the remaining three compartments.

Originality and fitness for purpose in its broadest sense

Originality

The scholarship standard requires technological practice that shows elements of elegance and/or originality – so Lesley Pearce, Genna’s teacher, expects her scholarship students to be able to argue convincingly that the outcome they have in mind will be original.

In Genna’s case, her four-compartment bag with separable compartments was an original and elegant solution to the “one size does not fit all” problem. If commercially produced, customers could purchase and/or use some or all of the compartments depending on their needs.

The design incorporated hidden key and phone pockets, and it was enhanced by the applied kiwi design.

Fitness for purpose in its broadest sense

Scholarship also requires that an outcome be fit for purpose "in its broadest sense". This refers not only to the fitness of the outcome, but also to the fitness of the practices used to develop the outcome. Two of the major considerations for Genna were place of potential manufacture and environmental impact.

Genna investigated the requirements for qualifying for a Kiwimade label if she were to go ahead and have her bag mass-produced. She found that either much of the making would need to be done in New Zealand or the materials used would need to be substantially made in New Zealand. She concluded that manufacturing her bag in New Zealand would not be a realistic option as we cannot compete with the much lower cost of labour in Asian countries.

Genna carefully investigated which materials and construction methods would ensure a durable and long-lasting bag. She identified that natural fabrics would not offer the durability of man-made fabrics, though their environmental impact may have been slightly less. She also found that producing natural materials can often have major environmental impacts. In the case of cotton, these include extensive use of chemicals for pest and weed control and large amounts of water to process the raw fibres into finished cloth.